Tesla’s era of flush, hidden door handles—part of its minimalist look and focus on aerodynamics—may be nearing an end. China’s Ministry of Industry and Information Technology (MIIT) has published detailed draft regulatory materials setting tougher safety expectations for vehicle door entry systems.

At the same time, Tesla is facing scrutiny in the United States through a new federal investigation by the National Highway Traffic Safety Administration (NHTSA). Together, these developments point to a clear direction: in an emergency, the way to open a vehicle door must be obvious, mechanical, and usable without special knowledge.

For Tesla, that could require rethinking one of its most recognizable design choices.

China’s new standard

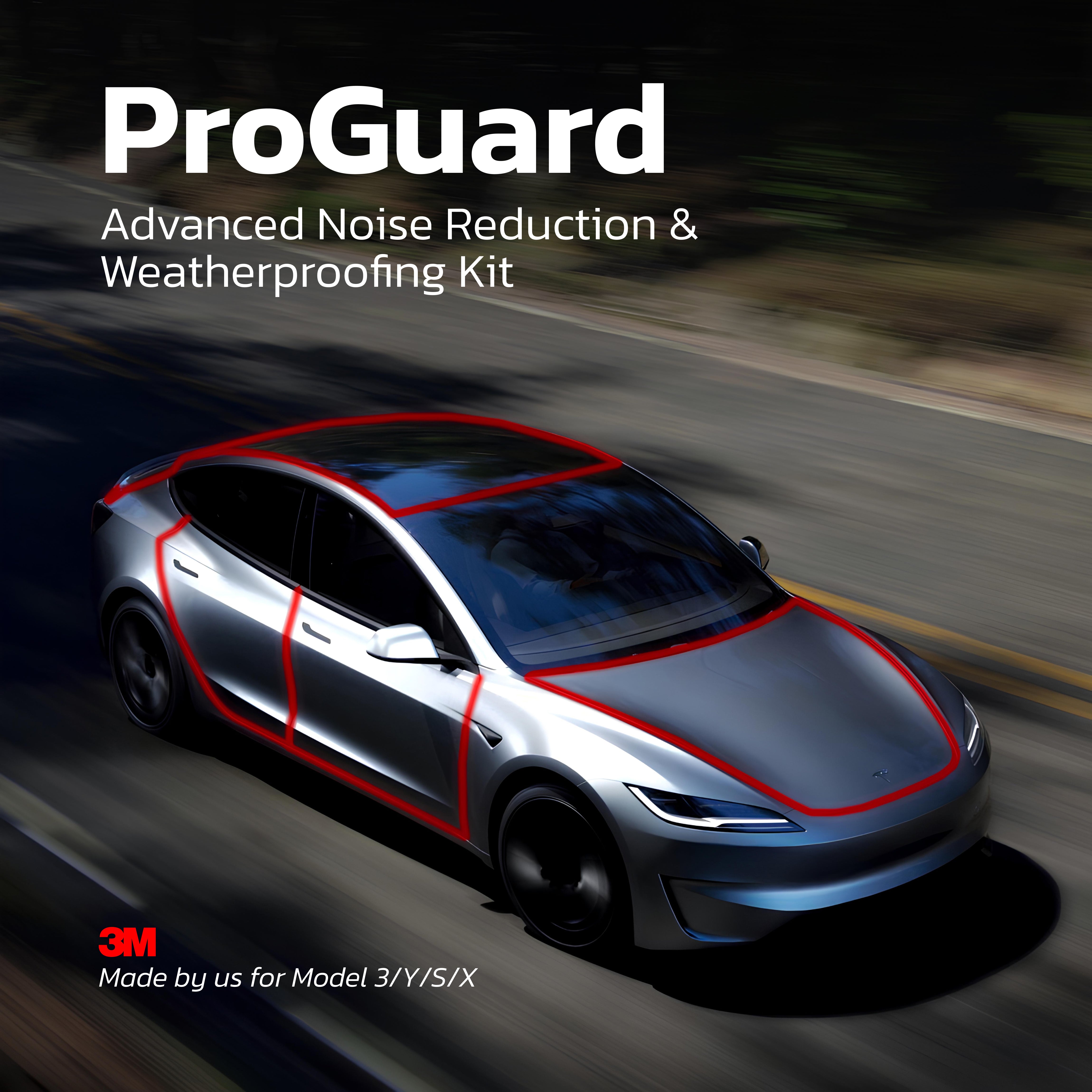

The requirements appear in a draft titled Safety Technical Requirements for Car Door Handles, released by MIIT on December 16, 2025. Although it is a domestic Chinese standard, Tesla’s large manufacturing presence at Giga Shanghai means the guidance could shape not only vehicles sold in China, but also broader design and production decisions—especially as similar concerns are being raised by U.S. regulators.

The draft is aimed at removing confusion during emergencies. It specifies that vehicle doors must include a mechanical release door handle that functions as a fail-safe if electronic power is lost. Regulators also emphasize usability: the mechanism must be clearly identifiable and operate within a defined physical space so it can be easily manipulated.

The goal is straightforward—someone unfamiliar with the vehicle should still be able to open the door in a crisis. That’s a known challenge today, even with Tesla’s popularity; many people still hesitate or fumble when trying to use the Model 3 and Model Y’s exterior handles because the operation isn’t immediately obvious.

Interior emergency egress

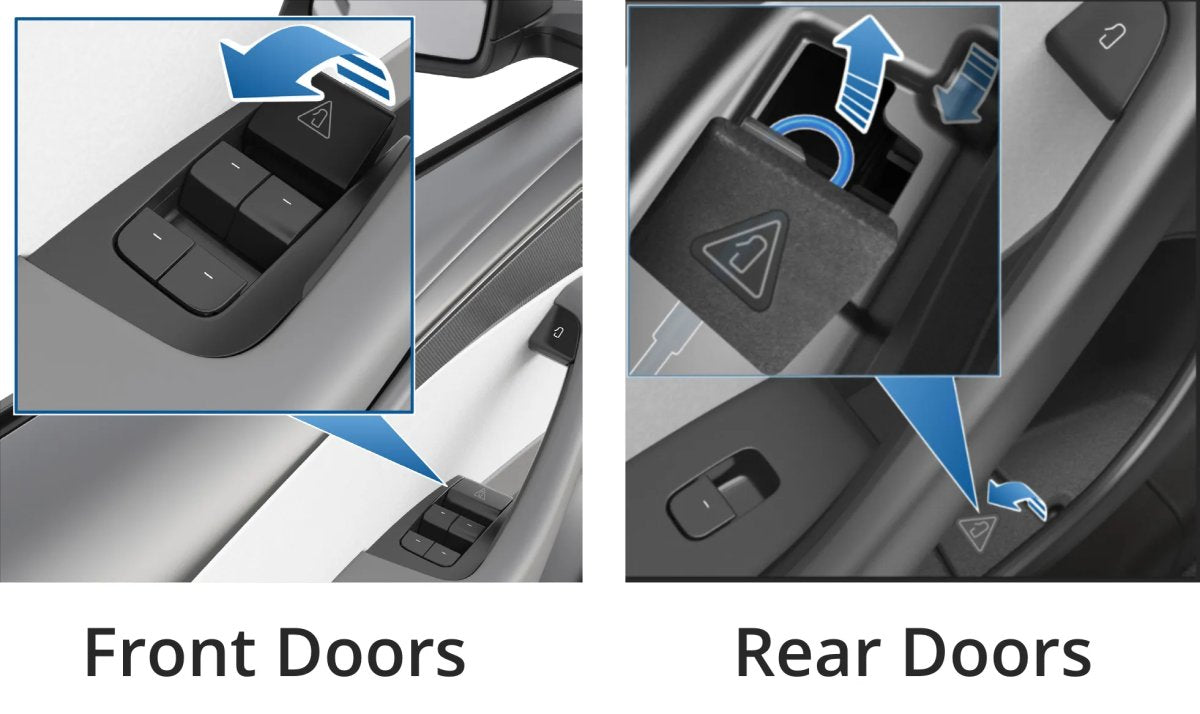

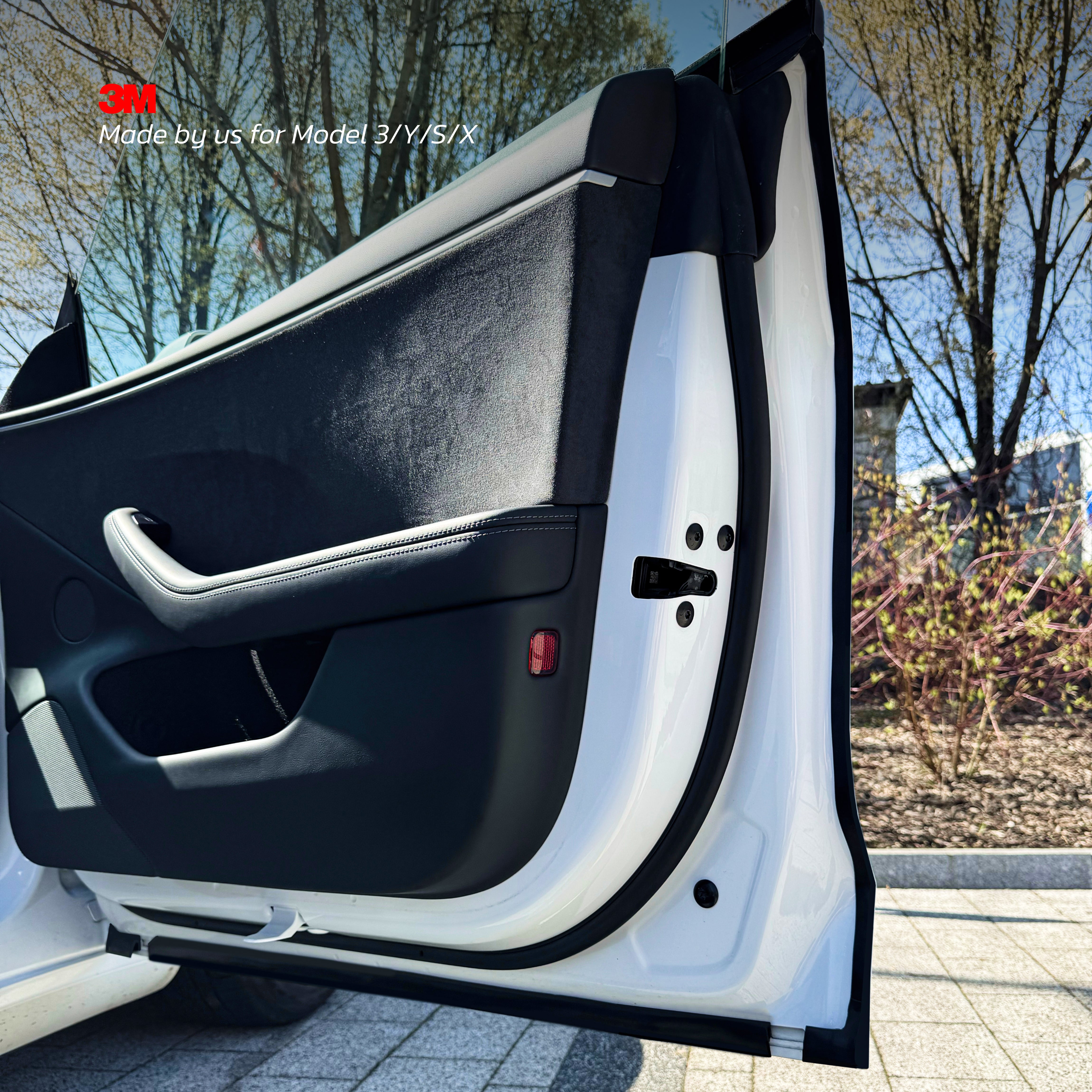

These proposed rules also conflict with parts of Tesla’s current interior approach, which can require significant changes. On the Model 3 and Model Y, rear-door mechanical emergency releases are tucked under compartments or behind trim—hard to spot quickly under stress. The Model X is often cited as the most difficult, because accessing the Falcon Wing Door emergency release can require partially disassembling the speaker area.

The NHTSA investigation

In the United States, the NHTSA opened a Defect Petition (DP25002) in late December to examine the safety of Tesla’s electronic door latches. The review follows reports that occupants were unable to exit during low-voltage power failures because they could not find the manual emergency release quickly and safely.

With China proposing proactive standards and the U.S. pursuing a reactive investigation, Tesla may find it increasingly difficult to keep its current approach unchanged.

A likely interior solution

Even as regulators push for change, Tesla appears to be developing an answer. Earlier this year, Head of Design Franz von Holzhausen acknowledged the concern and indicated Tesla was already engineering a solution to better combine electronic convenience with mechanical safety.

One probable direction is a unified interface that combines the electronic and mechanical releases into a single primary handle. Today, Tesla’s interior button or handle typically triggers an electronic actuator; if power is unavailable, the occupant must know where a separate manual release is located.

Under a unified design, the same handle could perform both functions: the initial movement would activate the electronic switch and open the door normally when the vehicle has power. If power is lost, pulling the same handle further would engage a mechanical linkage that physically unlatches the door.

Reducing the “panic factor”

This type of progressive latch concept is already used by other automakers. It could satisfy China’s requirement that a mechanical release be clearly identifiable, while still fitting a clean, simplified interior.

It also aligns with instinct. In a stressful situation, people typically pull harder when a door doesn’t open. If the mechanical fail-safe is activated by continuing the same pulling motion, the design reduces reliance on hidden releases buried under trim or inside compartments.

What changes outside may be needed

The Chinese draft also points to potential changes for exterior door hardware. Tesla’s flush handles have long been part of its design identity and contribute to reduced drag and improved efficiency. But requirements tied to accessibility and usable operating space can conflict with flush, low-profile designs.

In a serious crash with power loss, the Model 3 and Model Y’s exterior handles can still be operated, but the Model S may present a different issue: its handles can remain retracted and become difficult or impossible to use. More broadly, the current approach can be unintuitive for bystanders or first responders, especially if they are unfamiliar with Tesla’s handle mechanics.

Tesla may need to revise the Model S approach to meet the new expectations. At the same time, the Model 3 and Model Y could move toward a clearer “one-motion” interaction that naturally transitions from electronic operation to mechanical release.

Global design implications

While China’s requirements remain in draft form, timelines matter. The standards indicate late 2027 as the requirement date, which could place redesigned hardware on vehicles as early as late 2026 or early 2027.

Given Tesla’s preference for manufacturing simplification, it’s unlikely the company would want separate door systems for different regions. A single redesign that satisfies the stricter safety approach could become the default worldwide.

Partager:

Tesla Launches Model Y Standard in Canada and Standard Long Range in Europe

Tesla Launches 7-Seat Model Y in US, Bigger Screen, Dark Badging and Headliner, New Wheels